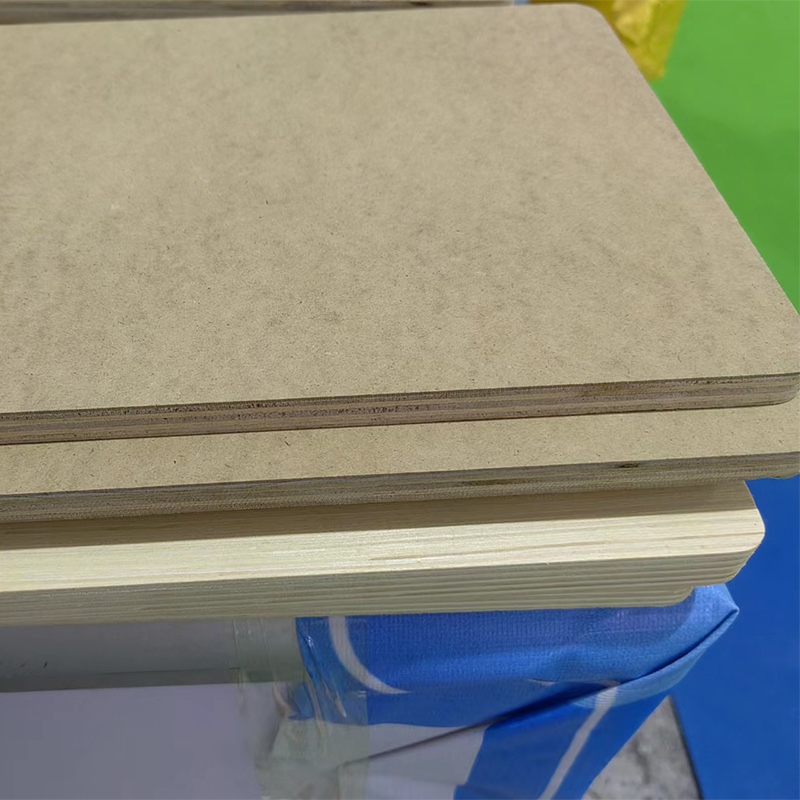

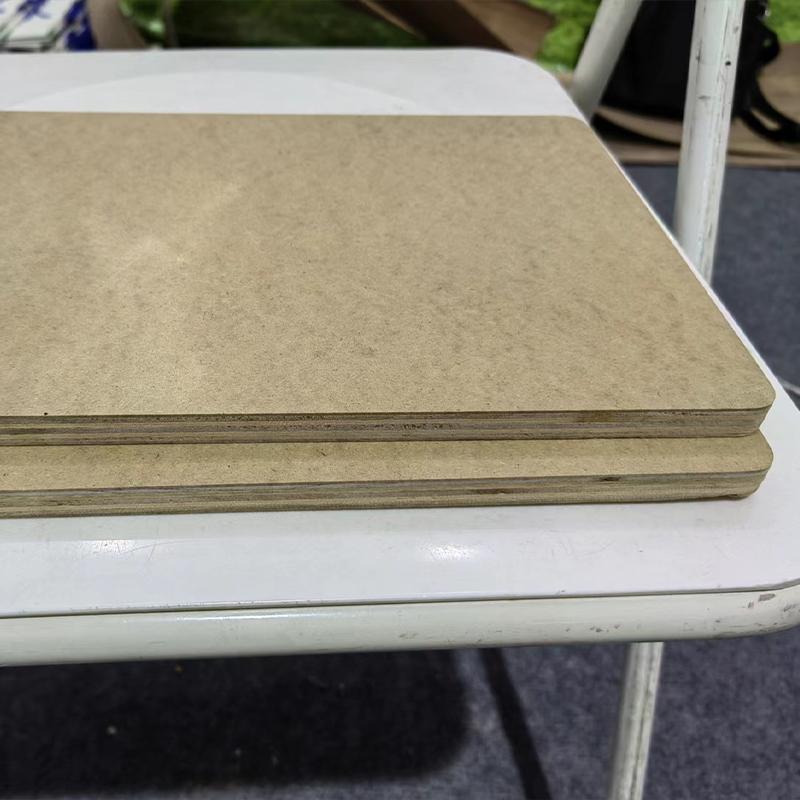

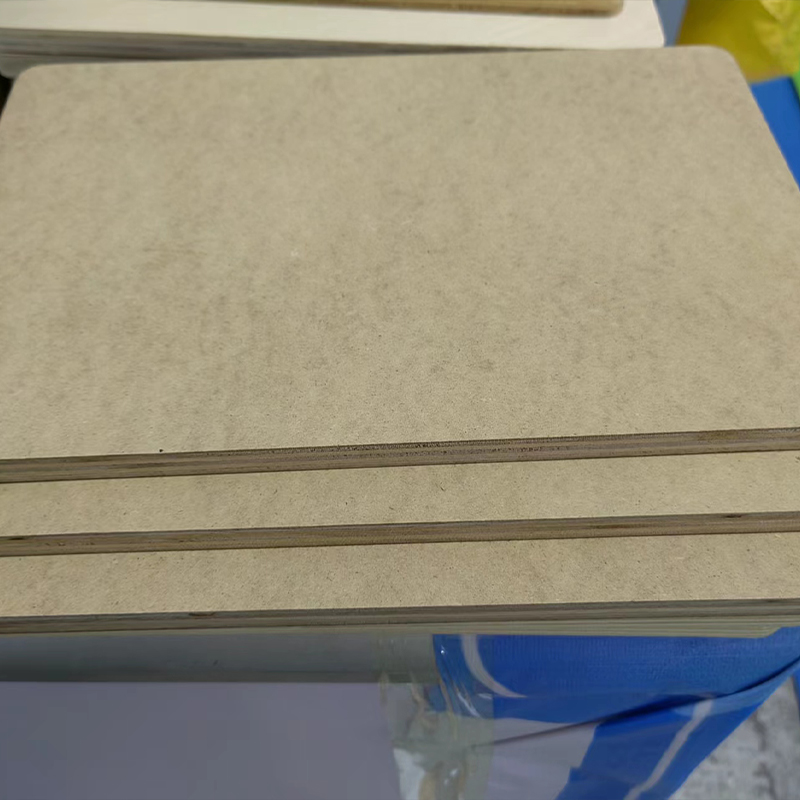

What Is Mdf Wood? Advantages & Disadvantages Explained

Pingyi Shengda Wood Co., Ltd

Add: Pingyi Linyi Shandong China www.yayouplywood.com plywoodjx@163.com Mobile: +8613792996881

This is Grace Xue working in Pingyi Shengda Wood Co., Ltd.from Linyi city Shandong province China.

We are group company have more than 800 persons producing high quality Commercial Plywood, Melamine Plywood, LVTT Plywood, Marine plywood,Craft Plywood, Fire-rated Plywood ect. Our products can be used for high quality furniture, cabinet,door, decoration ect. The plywood surface can be UV,painting, and laminated ect.

|

No. |

thickness (mm) |

ply |

PCS/ 40HQ |

CORE |

f/b |

plywood grade |

using |

Glue |

||

| core items | core grade | core mix | ||||||||

|

1 |

3 |

3 |

5706 |

poplar, eucalyptus, combine core |

whole piece, 2ed grade . |

1.one layer machine make, one layer man make up. 2.all machine core. |

okoume, bintangor, artification veneer, birch, pine, bleeched poplar, oak, with MDF f/b plywood, ect. |

UV, painting, laminating, fire resistant. more length plywood. |

furniture, cabinet, door panel, bending board, |

E0, E1, E2, melamine, WBP |

|

2 |

5(4.2) |

3 |

4080 |

|||||||

|

3 |

5(4.6) |

3 |

3726 |

|||||||

|

4 |

6 |

3 |

2862 |

|||||||

|

5 |

7 |

5 |

2448 |

|||||||

|

6 |

8 |

5 |

2141 |

|||||||

|

7 |

9 |

5 |

1890 |

|||||||

|

8 |

10 |

7 |

1710 |

|||||||

|

9 |

12 |

9 |

1422 |

|||||||

|

10 |

16 |

10 |

1080 |

|||||||

|

11 |

18 |

11 |

954 |

|||||||

|

12 |

20 |

13 |

864 |

|||||||

|

13 |

22 |

774 |

||||||||

|

14 |

25 |

684 |

||||||||

|

15 |

27 |

630 |

||||||||

|

16 |

28 |

612 |

||||||||

|

17 |

29 |

594 |

||||||||

|

18 |

30 |

576 |

||||||||

|

19 |

40 |

432 |

||||||||