Top Suppliers Commercial Plywood Cost - High Quality CDX Plywood For Floor Underlayment – YAYOU

Top Suppliers Commercial Plywood Cost - High Quality CDX Plywood For Floor Underlayment – YAYOU Detail:

Product Introduction

Plywood can impact the overall durability, lifespan, and longevity of construction. It also determines the need and frequency to maintain a particular element in construction projects, therefore it is necessary to consider the pros and cons of all the variety of it available in the market. So whether it may be used for a small bookshelf or an entire house, the type of plywood will make the entire difference to determine the product’s longevity. Therefore, CDX Plywood over the years has been one of the trusted choices when thinking of plywoods.

Let’s look at the plywood CDX and identify why this material is getting the hype in the new age!

The name itself can tell you a lot about the plywood CDX, it is a combination of ratings that give information about the quality as well as the construction of plywood. This can be evaluated by colour, durability factors and much more. After this, the rating systems are attached to the rank of A, B, C or D where their finesse goes from the chronology mentioned. A or B is more expensive types of CDX Plywood, whereas C & D are more economical and cheaper.

The mention of ‘X’ in CDX Plywood denotes the layers of plywood veneers that are glued together to make one. The quality will also depend on the type of wood and glue used, making it more or less susceptible to harsh environmental conditions. When it’s about CDX Plywood the ‘X’ also signifies the exposure that denotes its water-resistant qualities.

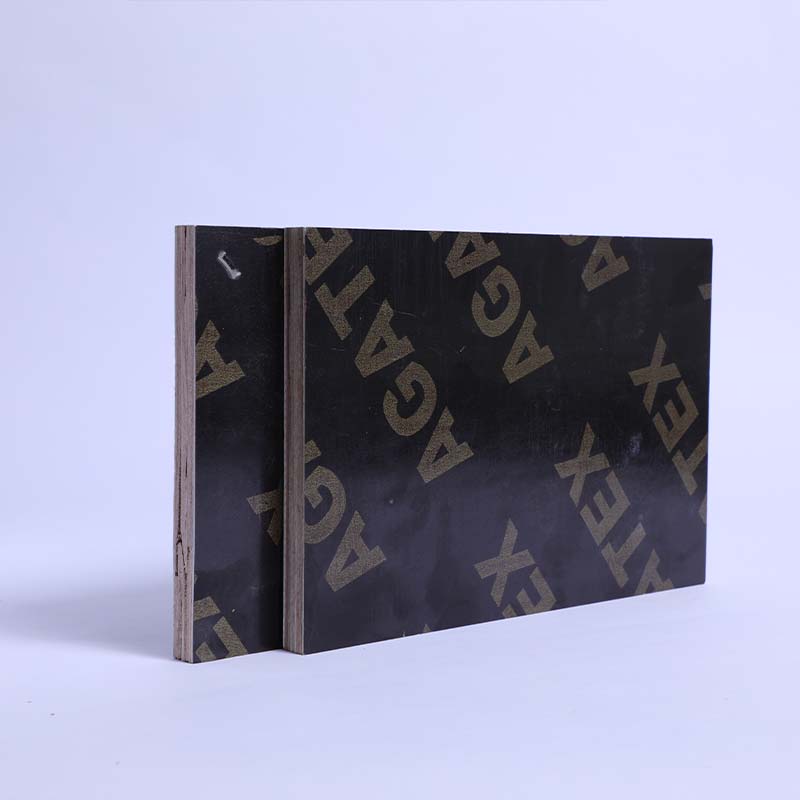

These plywood are made by binding 3 layers together where the finished product has different grades of veneer on both sides. CDX also symbolises the quality of the veneer used. It is available in varied sizes from 3/4 cdx plywood, 1/2 cdx plywood and much more.

While creating these plywoods the maker carefully aligns all the layers to reduce their shrinkage over time. The better layers are kept on the outside to avoid wear and tear. It is therefore ranked as one of the most convenient plywoods to be used.

Product Application

It is suitable for home building projects, including interior as well as exterior. For external surfaces, the contractors usually use CDX Plywood for walls and roofs. It is not used as a primary material in this case. But you will find them used in areas like roof shingles, roofing felt, sliding, insulations, etc.

For the interiors, CDX plywood is used as a flooring layer that can be below a carpet pad or backer board for tiling purposes. It is also used for other minor utility activities like shelving, basements, storage, cabinets, etc. It is usually not opted for furniture elements as you need much more finesse based details for such products.

Size: 1220x2440x12mm,1220x2440x18mm.

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for Top Suppliers Commercial Plywood Cost - High Quality CDX Plywood For Floor Underlayment – YAYOU , The product will supply to all over the world, such as: UAE, Tajikistan, Philippines, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!