Chinese Wholesale Film Faced - Smooth Waterproof Grade Film Faced Plywood – YAYOU

Chinese Wholesale Film Faced - Smooth Waterproof Grade Film Faced Plywood – YAYOU Detail:

Product Introduction

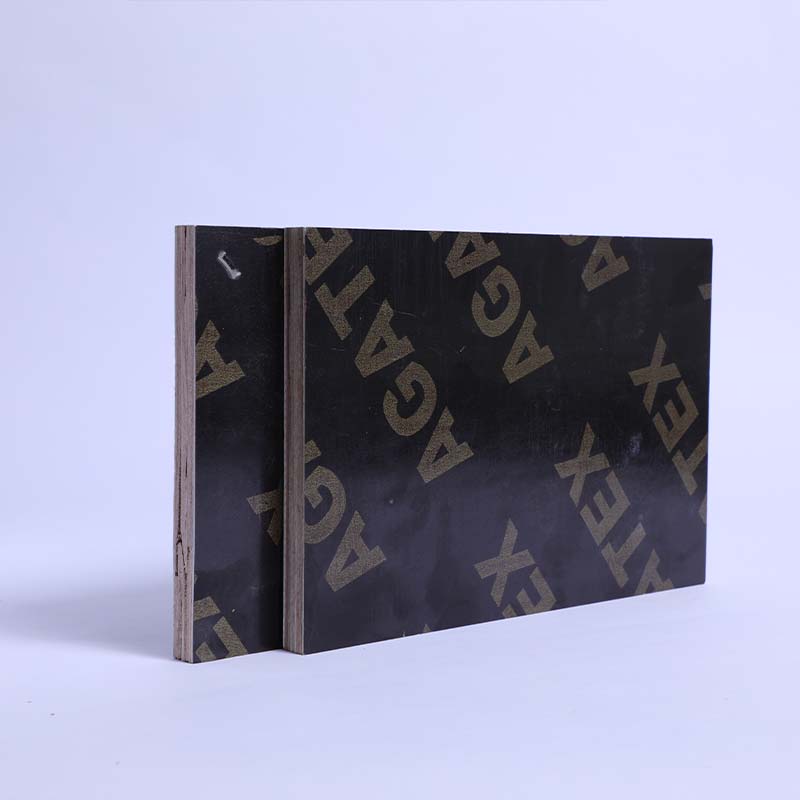

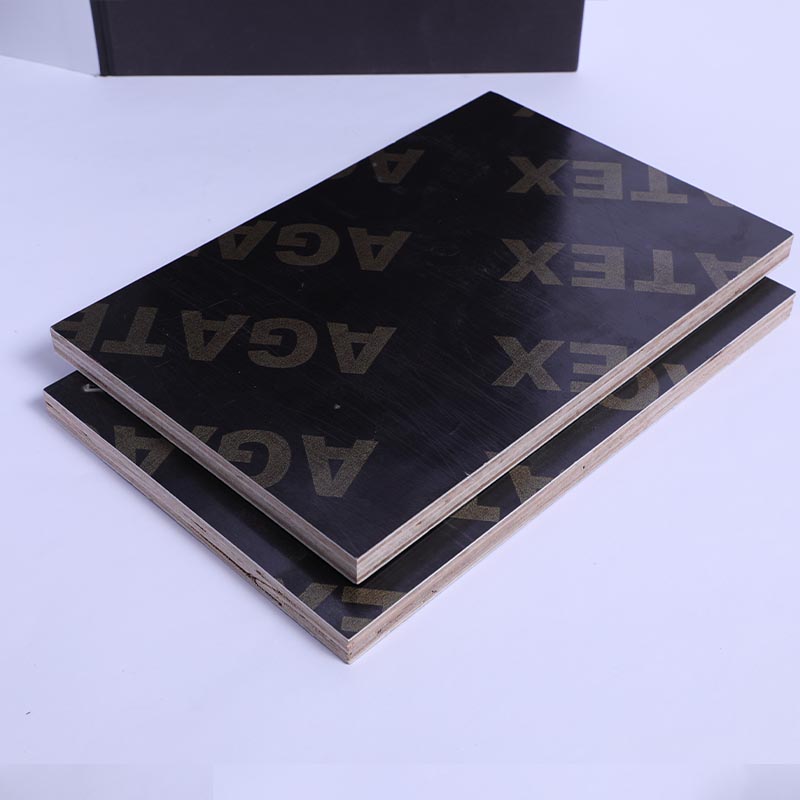

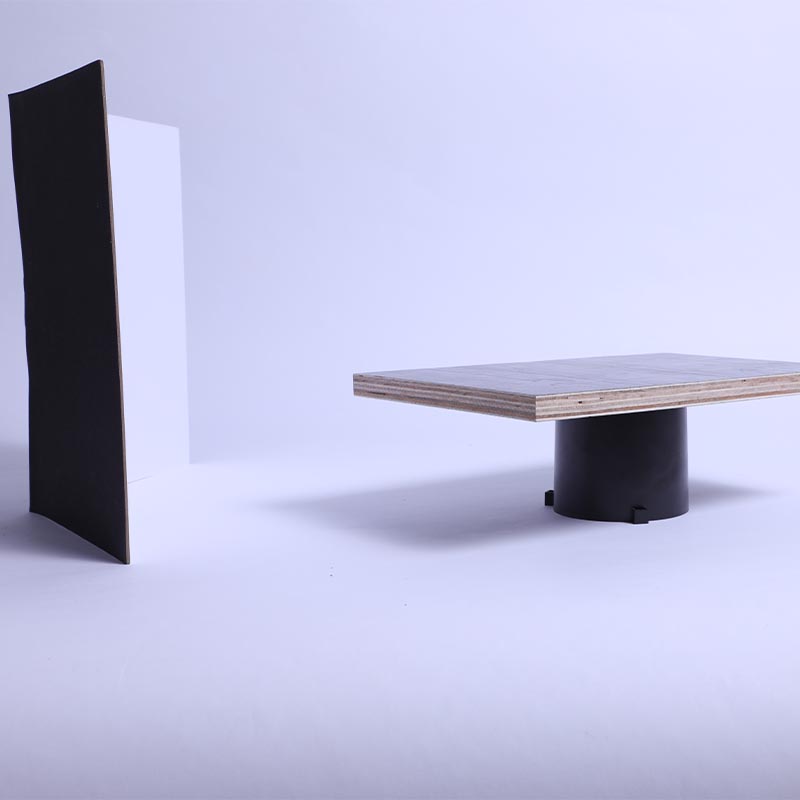

Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO (MDO plywood) and HDO (HDO plywood). The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film faced plywood can be used in harsh and outside environment: shuttering plywood, formwork plywood, concrete formwork, floorboard, vehicle building.

Specification of Film Faced Plywood

Film color: brown, black or others

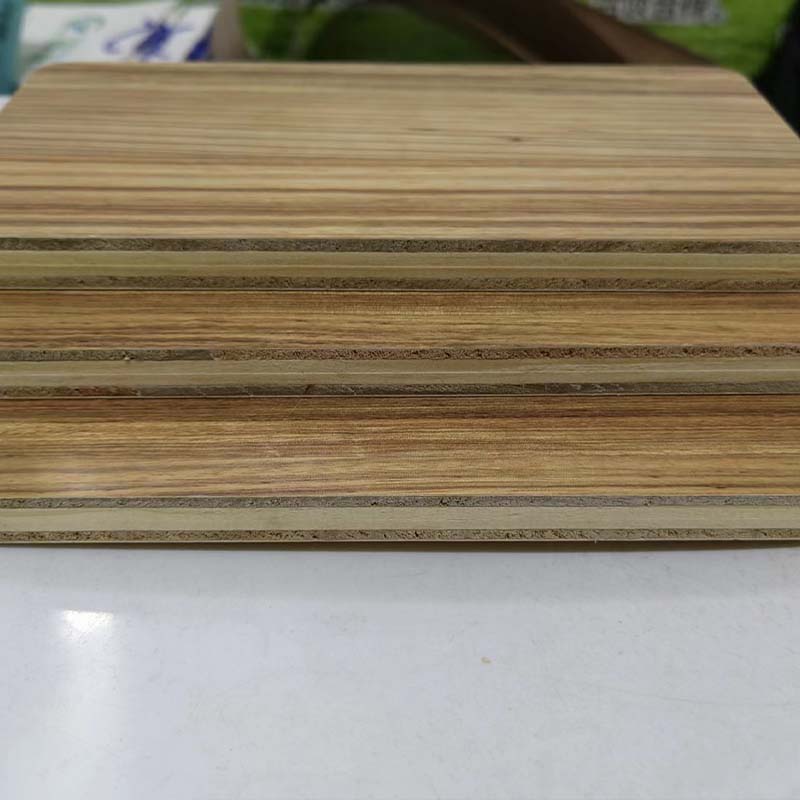

Core: poplar, eucalyptus, combine core

Glue: melamine, WPC

Size: 1220x2440mm, 1250x2500mm

Thickness: 9mm, 12mm, 15mm, 18mm

Features Of Film Plywood

1. The plywood a higher resistance to moisture, abrasion, chemical degradation and fungal attack compared to ordinary plywood.

2. Unlike regular plywood, film faced plywood is durable against concrete and as such is widely used in panel formwork.

3. Film faced plywood comes with a smooth or a mesh surface. Edges are sealed with water-dispersible acrylic paint.

4. Widely used in construction industry and vehicle production. Easy to mount and work with.

5. Film faced plywood is light weight, waterproof, easy to combine with other materials, easy to clean and cut.

The most popular application of film faced plywood in construction is concrete formworks. Shuttering boxes made of laminated plywood are more resilient and durable and can be used more than once before replacing.

The application of film faced plywood is not restricted to housing construction. For example, the construction of dams also frequently requires the use of overlaid plywood. It does not lose its shape and structural integrity under high loads and can withstand the force of fast-flowing water.

Pallet packing then load into container

Delivery time: within 25 days after receive payment.

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Chinese Wholesale Film Faced - Smooth Waterproof Grade Film Faced Plywood – YAYOU , The product will supply to all over the world, such as: Palestine, Rome, Washington, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,